Precise. Economical. Flexible.

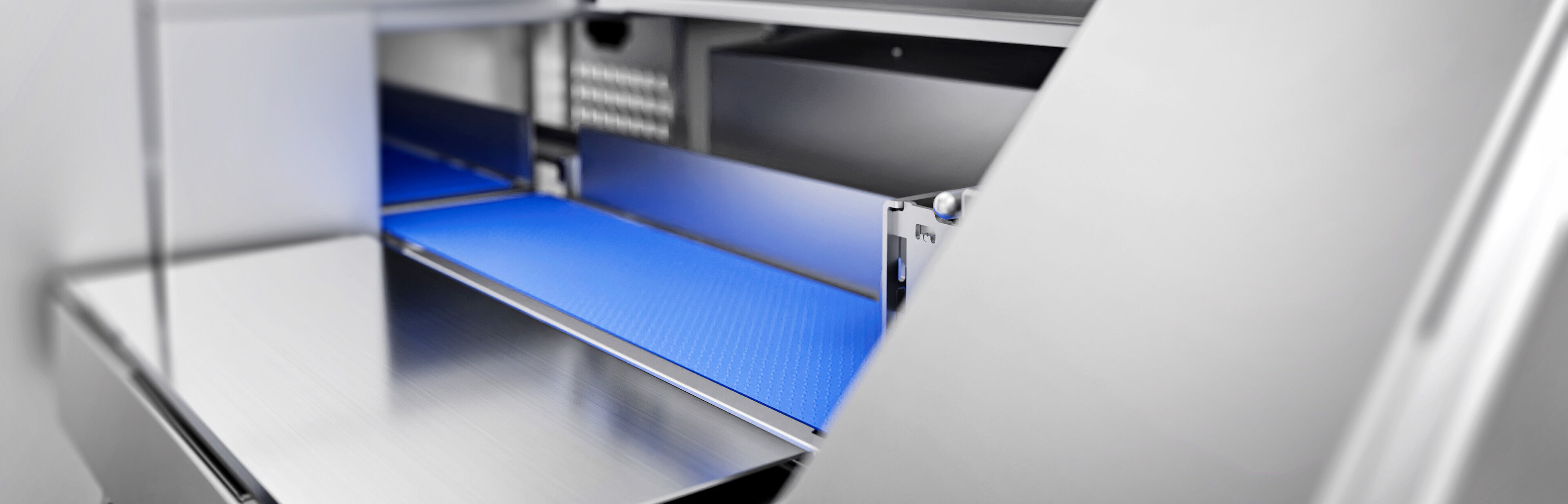

FS 800

Perfect cutting technology for industry and trade

The MHS FS 800 is a powerful and compact slicer that is perfect for both industrial applications and growing craft businesses. It combines state-of-the-art cutting technology with high precision to ensure exact portioning and maximum efficiency. The machine is particularly flexible and can be easily adapted to different product types, from meat and sausage products to cheese and convenience products. Thanks to the innovative 360° scanner technology, each product and its individual characteristics are precisely recorded, ensuring accurate cutting and minimising material loss.

With an impressive output of up to 400 cuts per minute, the FS 800 increases productivity while ensuring the highest cutting quality. The user-friendly control via a modern full HD touchscreen display ensures easy operation even without prior knowledge. The open design of the machine makes cleaning much easier, ensuring the highest standards of hygiene.

The FS 800 is the perfect solution for companies that rely on economical, efficient and high-quality food processing.

Intuitive &

User-friendly

- Full HD touchscreen for simple and intuitive control without prior knowledge

- Storage of up to 100 cutting programmes for efficient processes

- Network-compatible for remote maintenance and software updates

- Intuitive service menu for quick fault diagnosis directly on the display

- Flexible adjustment options for process parameters before and during cutting for optimum results

Innovative

cutting technology

for maximum precision

- Optimum product fixation - new hold-down system from above for maximum stability and precise cuts

- MHS micro-serration - precise cuts, even with bone products

- Intelligent scanner technology - automatic adjustment to the size, shape and texture of the product

- Up to 400 cuts per minute - maximum efficiency for high production output (300 cuts per minute in scanner mode)

- Pneumatic grippers with automatic waste ejection - for continuous work without interruptions

- Perfectly aligned blade shaft position - high-precision cutting results, even with frozen products

This innovative technology ensures consistently precise portioning, minimised losses and maximum efficiency - even for the most demanding cutting tasks.

Hygiene and

easy cleaning

- Open design - optimum accessibility for thorough cleaning

- Quick disassembly - cutting frame and gripper can be easily removed

- Designed for industrial cleaners - maximum hygiene without compromise

- Cleaning trolley & blade guard - safe and hygienic storage after cleaning

Flexible

Gripper technology

- Combination of manual & automatic gripper - can be used flexibly depending on product requirements

- Manual intervention possible - ideal for difficult products

- Automatic gripper in the standard process - for efficient and smooth processes

- Perfectly adapted claws - maximum stability right up to the last cut

Precision and efficiency with

360° scanner technology

The FS 800 ensures exact cuts and maximum material utilisation thanks to a state-of-the-art 360° scanner with high-precision cameras and laser sensors. Each product is fully scanned, weighed and analysed to achieve perfect cutting results.

- Automatic adjustment of cutting thickness - for precise weight or thickness portioning

- Maximum raw material utilisation - intelligent cutting process reduces waste and increases efficiency

- Consistent results - regardless of product variations for consistently high quality

- Maximum precision even with difficult shapes - perfect cuts even with uneven or natural products

- Economical & sustainable - less waste, more yield and optimal product presentation

Thanks to this innovative technology, you benefit from maximum cutting accuracy, reduced material losses and first-class product quality - for high efficiency in your production!

Versatile and

Efficient

- Up to 400 cuts per minute for maximum productivity

- Seamless integration into the production process thanks to various grouping options

- Precise fanning and separating of products with mobile outfeed belt

- Individually adjustable weight per slice and per portion.

- Optimum processing of a wide range of products, from bone-in products to delicatessen products

Versatile use for

a wide variety of products

The MHS FS 800 impresses with its ability to precisely slice both bone-in products, such as handle and neck chops, and boneless products, such as steaks, sausages and cheese.

Even slightly frozen food and food down to -8°C can be processed effortlessly.

Ideal for the exact portioning of convenience products such as roasts, meat loaf or meat loaf - for consistently high quality and maximum efficiency in production.

Technical

Data

| FS 800 | |

| Max. input length (in mm) | 800 |

| Cross section mm (WxH) | 260 x 160 |

| Dimensions (WxDxH) W with Belt |

3300 x 1460 x 1720 4380 x 1460 x 1720 |

| Connection (other voltage on request) | 3 x 400 V + PE + N / 50 - 60 Hz / 11,5 kW |

| Weight (in kg) | 1500 |

| Performance slices/minute | 300 (scanning mode), 400 |

| Slice thickness (mm) | from 0,5 |

| Suitability | industry |

| Flap start | yes |

| Return travel limit | yes |

| Distribution of remaining slice | yes |

| Section software | yes |

![[Translate to Englisch:] PCE 65 TM](/fileadmin/_processed_/8/c/csm_PCE-65TM_gesamt_2024_b1db9d242e.png)

![[Translate to Englisch:] PCE KM](/fileadmin/_processed_/9/5/csm_PCE25KM_gesamt_4c08bf03a2.png)

![[Translate to Englisch:] PCE EM](/fileadmin/_processed_/d/0/csm_PCE25EM_gesamt_883aff0a3a.png)

![[Translate to Englisch:] MHS 850 / 1000](/fileadmin/_processed_/2/a/csm_mhs850_gesamt_14688182e9.png)

![[Translate to Englisch:] IC 70 / 100](/fileadmin/_processed_/7/f/csm_IC_gesamt_a3d348c09e.png)

![[Translate to Englisch:] FS 800](/fileadmin/_processed_/f/c/csm_fs800_gesamt_c88ce34d3c.png)

![[Translate to Englisch:] ICC 25 / 36](/fileadmin/_processed_/c/7/csm_ICC25_gesamt_b605b74a5b.png)

![[Translate to Englisch:] ICC 28](/fileadmin/_processed_/5/f/csm_ICC28_Gesamt_b77d0f91e6.png)