Effective. Continuous. Extra powerful.

ICC 25/36

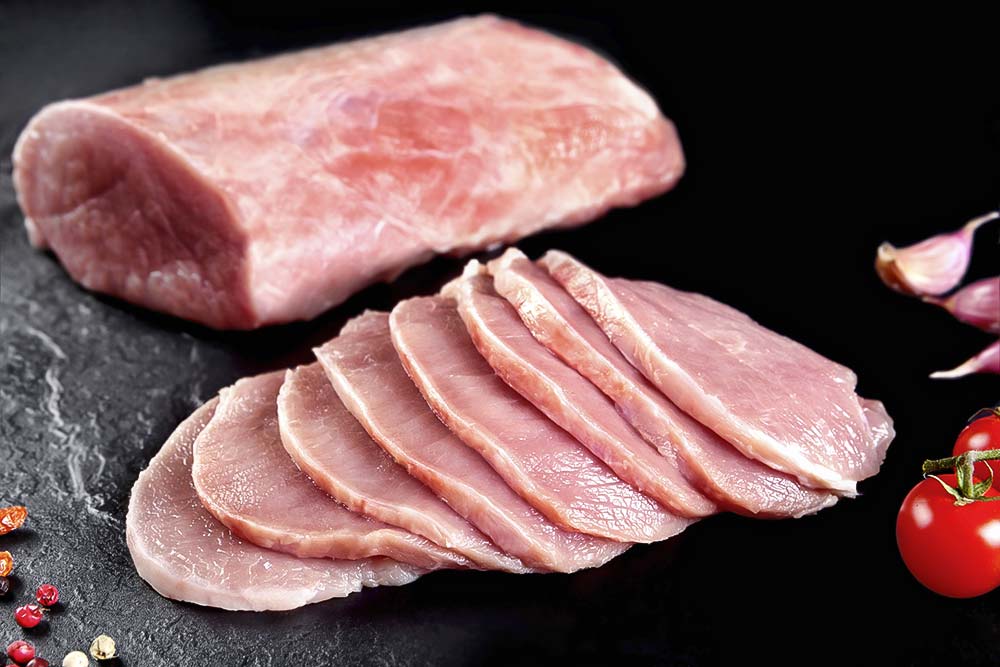

On The Fast Lane - Ideal for the meat industry

No waiting time thanks to continuous feeding. With the ICC 25/36, we reacted to our customers’ increasing needs. With throughput of up to 4000 kg per hour, you are on the fast lane. But we didn’t compromise on slicing quality. The advantage lies in the continuous production flow, as unlike with traditional machines, there are no waiting times caused by having to retract the gripper or open and close the flap.

The ICC 25/36 slices easily bone-in products such as meat, chops, neck or boneless products such as pork belly, roulades, roasts, sausages, cold cuts, cheese and fish.

Simple & uncomplicated

Operation

Immediately usable without long training periods for the staff.

- Clear touch display

- Up to 100 programs can be stored

- Highest safety level

- Optional step-by-step or continuous feed for uniform slices

- Automatic starting device

- Software update and data backup via USB stick/SD card

Smart

Cutting System

Cut your products fast, precise and reliable.

- Up to 500 or 1000 slices/minute (single or double blade operation)

- High cutting accuracy of the blade due to MHS micro toothing

- Slicing software for portioning

- Shorter cycles thanks to automatic return limiter

- Linear product feed

- Single cut function with higher blade speed increases slice quality on low production rate

- Exact feed due to friction-reducing surface

- Optimized hold of the product through MHS-toothed feeding belt and the product-adapting hold-down belts

- Product recognition enables the division of products into different sections

- Residual slice division for slicing the product without residues

Versatile &

Flexible

Perfectly matched to your needs.

- Different versions in product width

- Variable in product length

- Outfeed belt available in different lengths

- Adjustable speed from 60 sections/minute

- Easy integration into production line

- Optionally available with underfloor belt for improved production flow

Maximum

Hygiene

Easy and fast cleaning.

- Good accessibility to the individual components

- Easy to clean in just a few steps

- Complete closed and encapsulated housing

- Including cleaning mode

Multiple

Cuttion options

- Slicing fresh boneless and bone-in meat products frozen to -4°C into uniform slices

- Slicing of cooked products, sausage and cheese, fish

- Slice thickness from 0.5-500 mm possible

- Optional with double blade for cutting butterfly steaks

- Shingling and separation of products in conjunction with a conveyor belt

Technical

Data

| ICC 25 | ICC 36 | |

| Max. input length (in mm) | variable | variable |

| Cross section mm (WxH) | 250 x 180 | 360 x 180 |

| Dimensions (WxDxH) in mm | 3600 x 1050 x 1650 | 3600 x 1230 x 1650 |

| Connection 3Ph + PE (other voltage on request) | 8,6 kW 400 V / 230 V / 208 V / 50 Hz / 60 Hz | 9,5 kW 400 V / 230 V / 208 V / 50 Hz / 60 Hz |

| Weight (in kg) | 720 | 900 |

| Performance single blade slices/minute | 500 | 500 |

| Slice thickness (mm) | 0,5 - 500 | 0,5 - 500 |

| Suitability | industry | industry |

| Startup system | yes | yes |

| Cutting software | yes | yes |

| Distribution of remaining slice | yes | yes |

| Section software | yes, up to 5 sections | yes, up to 5 sections |

![[Translate to Englisch:] PCE 65 TM](/fileadmin/_processed_/8/c/csm_PCE-65TM_gesamt_2024_b1db9d242e.png)

![[Translate to Englisch:] PCE KM](/fileadmin/_processed_/9/5/csm_PCE25KM_gesamt_4c08bf03a2.png)

![[Translate to Englisch:] PCE EM](/fileadmin/_processed_/d/0/csm_PCE25EM_gesamt_883aff0a3a.png)

![[Translate to Englisch:] MHS 850 / 1000](/fileadmin/_processed_/2/a/csm_mhs850_gesamt_14688182e9.png)

![[Translate to Englisch:] IC 70 / 100](/fileadmin/_processed_/7/f/csm_IC_gesamt_a3d348c09e.png)

![[Translate to Englisch:] FS 800](/fileadmin/_processed_/f/c/csm_fs800_gesamt_c88ce34d3c.png)

![[Translate to Englisch:] ICC 25 / 36](/fileadmin/_processed_/c/7/csm_ICC25_gesamt_b605b74a5b.png)

![[Translate to Englisch:] ICC 28](/fileadmin/_processed_/5/f/csm_ICC28_Gesamt_b77d0f91e6.png)